Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Evolution, Challenges, and Opportunities in Ready Mix Concrete (RMC) Industry in India

Authors: Vipin Khade, Sanjay Joshi

DOI Link: https://doi.org/10.22214/ijraset.2024.63294

Certificate: View Certificate

Abstract

The Ready Mix Concrete (RMC) industry has undergone significant evolution since its inception, transforming the construction landscape with its efficiency and reliability. This paper provides a comprehensive analysis of the evolution of the RMC industry, tracing its origins, key milestones, and technological advancements. It also examines the challenges facing the RMC sector, including regulatory hurdles, supply chain constraints, and environmental concerns. Furthermore, the paper explores the opportunities for growth and innovation within the RMC industry, such as embracing digitalization, sustainable practices, and market diversification. By understanding the evolution, addressing the challenges, and seizing the opportunities, stakeholders can navigate the dynamic landscape of the RMC industry and drive its continued advancement.

Introduction

I. INTRODUCTION

In contemporary Indian construction practices, Ready Mix Concrete (RMC) has emerged as a cornerstone, revolutionizing the way infrastructure projects are executed. RMC offers a blend of efficiency, quality, and sustainability, addressing the evolving needs of the construction industry. In modern construction practices, Ready Mix Concrete (RMC) holds significant importance due to its efficiency, consistency, and quality. Unlike traditional on-site concrete mixing, RMC is manufactured in centralized batching plants according to precise specifications, ensuring uniformity in every batch. This consistency translates to enhanced structural integrity, durability, and overall construction quality.The purpose of this paper is to delve into the evolution, challenges, and opportunities within the RMC industry. It aims to provide a comprehensive understanding of how RMC has evolved over time, the challenges it faces in today's market, and the various opportunities for innovation and growth.By examining the historical development of RMC, we can gain insights into the factors driving its adoption and the technological advancements that have shaped its evolution. Additionally, the paper will explore the challenges confronting RMC producers, such as fluctuating raw material costs, regulatory compliance burdens, environmental concerns, and intense competition. Moreover, the paper will identify opportunities for RMC producers to overcome these challenges and thrive in the industry. This includes leveraging advanced technologies for automation and quality control, capitalizing on sustainability initiatives through eco-friendly concrete solutions, and expanding market presence through geographic diversification and value-added services.

II. EVOLUTION OF THE RMC INDUSTRY TRACING THE HISTORICAL EVOLUTION OF THE RMC INDUSTRY

Although concrete was initially patented in Germany in 1903, the idea could not be widely used for commercial purposes at that time due to inadequate transportation technology. The first rotating drum type transit mixer truck —of far lesser capacity than those available today—was created in 1916, and a first commercial supply of RMC was made in Baltimore, USA, in 1913. In some European nations, RMC had been implemented by the late 1920s and early 1930s. In India, ready-mixed concrete factories were introduced in year 1950s, but their application was restricted to big construction projects like dams. The dams at Bhakra and Koyna were among the first projects to use RMC.

Beginning with the initial ready-mixed concrete infrastructure for commercial use. The number of RMC plants has increased over the ten years, with the first commercial plant opening in Pune in 1992. Since then, India has seen a sharp increase in the number of RMC plants. The housing and infrastructure sectors, which are the two main areas of national planning emphasis, have been calling for faster and higher-quality concrete. Smaller cities and villages have seen an expansion of the RMC industry over time, in addition to major cities. According to current estimates, India manufactures 35–40 million m3 of concrete annually from about 3881 RMC factories spread throughout the nation.

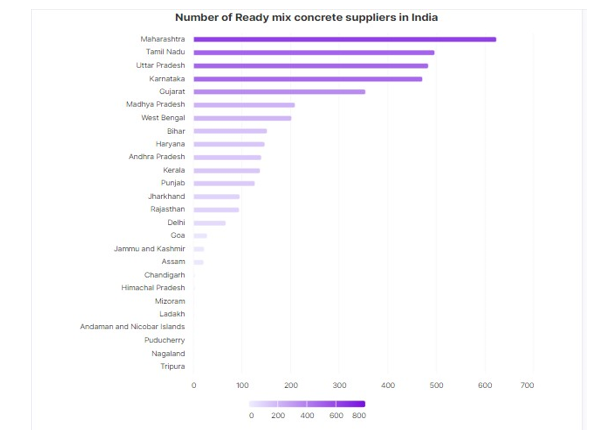

Number of Ready mix concrete suppliers locations by each State

State Number Of Ready mix State Number Of Ready mix

concrete suppliers concrete suppliers

Maharashtra 625 Rajasthan 95

Tamil Nadu 497 Delhi 67

Uttar Pradesh 484 Goa 29

Karnataka 472 Jammu And Kashmir 23

Gujarat 355 Assam 6

Madhya Pradesh 210 Chandigarh 4

West Bengal 203 Himachal Pradesh 3

Bihar 152 Mizoram 2

Haryana 147 Ladakh 2

Andhra Pradesh 140 Andaman And Nicobar Islands 1

Kerala 138 Puducherry 1

Punjab 127 Nagaland 1

Jharkhand 96 Tripura 1

III. CHALLENGES FACING THE RMC INDUSTRY

Examining the challenges confronting the RMC industry, such as regulatory constraints, supply chain disruptions, raw material availability, and environmental sustainability concerns.

The Indian Ready Mix Concrete (RMC) industry, despite its significant growth and adoption, faces several challenges that hinder its full potential. These challenges encompass regulatory constraints, supply chain disruptions, raw material availability, and environmental sustainability concerns.

- Regulatory Constraints: The RMC industry operates within a regulatory framework that often poses challenges in terms of obtaining permits, complying with standards, and navigating bureaucratic procedures. Complex regulations can lead to delays in project execution and increase operational costs for RMC producers.

- Supply Chain Disruptions: The RMC industry relies on a smooth and efficient supply chain to ensure timely delivery of concrete to construction sites. However, disruptions such as transportation bottlenecks, labor shortages, or unexpected events like natural disasters can hamper the supply chain, causing delays and cost overruns.

- Raw Material Availability: Availability and quality of raw materials, particularly aggregates and cement, are crucial for producing high-quality RMC. Fluctuations in the availability of these materials due to factors like seasonal variations, mining regulations, or transportation issues can impact the production capacity and consistency of RMC plants

- Environmental Sustainability Concerns: The RMC industry's operations have environmental implications, including energy consumption, carbon emissions, and waste generation. Balancing the need for construction materials with environmental sustainability goals poses a challenge for RMC producers. Moreover, stricter environmental regulations and increasing pressure to adopt eco-friendly practices necessitate innovative solutions for reducing the industry's carbon footprint and waste generation.

Addressing these challenges requires a multi-faceted approach involving collaboration among industry stakeholders, government bodies, and research institutions. Streamlining regulatory processes, investing in infrastructure development to improve transportation networks, promoting sustainable practices, and exploring alternative raw materials are some strategies that can help mitigate the challenges facing the Indian RMC industry. Additionally, leveraging technology and data-driven solutions can enhance efficiency, transparency, and resilience within the RMC supply chain, ultimately contributing to the growth and sustainability of the industry.

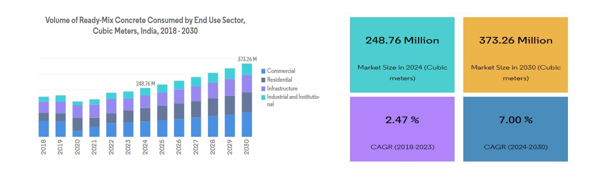

IV. FUTURE OF READY-MIX CONCRETE IN INDIA

The future of the RMC industry in India is promising, driven by urbanization, infrastructure development, sustainability imperatives, technological advancements, and evolving customer demands. RMC producers that adapt to these trends, innovate, and focus on delivering high-quality products and services are likely to thrive in the Indian construction market. India is experiencing rapid urbanization, with increasing migration to cities and towns. This trend fuels the demand for construction activities, including residential, commercial, and infrastructure projects, all of which require a reliable and efficient supply of concrete. The Indian government's focus on infrastructure development through initiatives like "Smart Cities Mission," "Housing for All," and investments in transportation infrastructure, such as highways, metro rail projects, and airports, will continue to drive demand for RMC. As construction practices evolve, there's a growing preference for ready-mix concrete due to its consistent quality, faster construction pace, and reduced on-site labor requirements. This trend is expected to further boost the adoption of RMC across various construction segments. The India Ready Mix Concrete Market size is estimated at 248.76 million Cubic meters in 2024, and is expected to reach 373.26 million Cubic meters by 2030, growing at a CAGR of 7.00% during the forecast period(2024-2030).

Demand for Ready-Mix Concrete (RMC) is rising sharply, mostly due to the government's emphasis on supporting infrastructure development. A major factor in this increase is urbanization; estimates show that India's urban population would expand from 518 million in 2023 to 542.7 million by 2025.

Forecasts indicate that the Indian real estate market would develop at an outstanding 19.5% compound annual growth rate (CAGR) from 2017 to 2028. By FY30, this trajectory is predicted to reach an astounding US$ 1 trillion valuation.

Major cities like Ahmedabad, Bangalore, Chennai, Hyderabad, Kolkata, Mumbai, Pune, and the National Capital Region (NCR) are major contributors to the notable rise in segments including luxury residences and organized retail real estate. Large-scale investments are anticipated in response to government programs like "Housing for All," while policy efforts such as 100% FDI in townships within Special Economic Zones (SEZs), Real Estate Investment Trusts (REITs), and Real Estate Bonds are increasing consumer demand. Initiatives such as GatiShakti Terminals and the anticipated increase of flexible spaces also point to a varied growth trajectory for the RMC market, which might reach a noteworthy US$ 7.7 billion by FY2030 and is bolstered by urbanization, changing family structures, and rising travel demands.

Conclusion

In conclusion, the research paper on the evolution, challenges, and opportunities in the Ready Mix Concrete (RMC) industry provides valuable insights into the dynamic landscape of this crucial sector within the construction industry. The evolution of the RMC industry from traditional on-site mixing methods to centralized batching plants underscores the industry\'s commitment to efficiency, consistency, and quality. This evolution has been driven by advancements in technology, changing construction practices, and the need for sustainable solutions. Despite the industry\'s advancements, it faces significant challenges such as fluctuating raw material costs, regulatory compliance burdens, environmental concerns, and intense competition. However, these challenges also present opportunities for innovation and growth. By proactively addressing challenges and leveraging opportunities, RMC producers can position themselves for sustainable success. Embracing technologies for automation, quality control, and digitalization can enhance efficiency and productivity. Additionally, capitalizing on sustainability trends through the development of eco-friendly concrete solutions can not only meet regulatory requirements but also appeal to environmentally conscious customers. Expanding market presence geographically and offering value-added services such as technical support and customized mix designs can further differentiate RMC producers in a competitive market. In conclusion, the RMC industry continues to play a vital role in the construction sector, offering efficient and reliable concrete solutions. Through strategic planning, innovation, and a commitment to quality, RMC producers can navigate challenges and seize opportunities to thrive in the evolving construction landscape. Top of Form Bottom of Form

References

[1] Manjunatha Lr and Sandhya R Anvekar History of ready-mixed concrete in India October 2015 [2] Mordorintelligence- industry-reports- India-ready-mix-concrete-market [3] Construction Times - Monthly Magazine [4] D. Gordon, P. Kshemendranath, setting up of Ready Mix concrete industry in india, international conference , Dundee, Sept 99. [5] Shailendra Chouksey -Ready Mix Concrete: An Industry Perspective on Challenges & Opportunities for Growth -GLOBAL RESEARCH ANALYSIS Oct 2012 •

Copyright

Copyright © 2024 Vipin Khade, Sanjay Joshi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63294

Publish Date : 2024-06-14

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online